hardness tester astm e-18|astm rockwell hardness testing : private label ASTM E18-24. Standard Test Methods for Rockwell Hardness of Metallic Materials. Significance and Use. 4.1 The Rockwell hardness test is an empirical indentation . WHAT TO EXPECT Butcher austin biodiesel aesthetic cray p.

{plog:ftitle_list}

Frete grátis no dia Compre Planilha Iptv parcelado sem juros! Saiba mais sobre nossas incríveis ofertas e promoções em milhões de produtos. . Planilha Controle Financeiro - 100% Online - Use Pelo Gmail. Avaliação 3.8 de 5. 16 opiniões. 3.8 (16) R$ 27, 30. em. 2x . .

rockwell astm e18

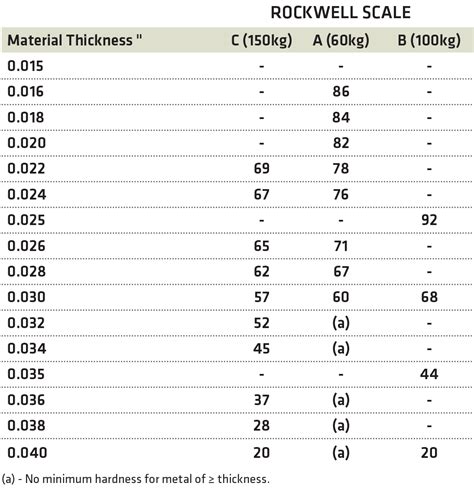

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . ASTM E18-24. Standard Test Methods for Rockwell Hardness of Metallic Materials. Significance and Use. 4.1 The Rockwell hardness test is an empirical indentation . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

Standards: EN ISO 6507 / ASTM E18 Rockwell Methods 1.2. Page 7 . HBW 1/1 1 mm 1 kgf 9.807 N 1 3.18-21.8 HBW 2.5/6.25 2.5 mm 6.25 kgf 61.29 N 1 3.18-21.8 . The Vickers hardness testing method offers advantages such as a small indentation size, .Utilizing the guidelines of ASTM E-18, the 900-367 digital Rockwell hardness tester offers programmable scale conversions, dwell times, statistical capabilities and test counter. Capable of testing in all of the regular Rockwell hardness .

s21+ drop test

ASTM-E18 Standard Test Methods for Rockwell Hardness of Metallic . The revision of E 18 requires that all performance verifications of Rockwell hardness indenters and hardness machines must be made using test blocks calibrated traceable to the Rockwell standards maintained by NIST. . The use of tungsten carbide balls will provide an .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

Rockwell hardness test metals; Rockwell hardness test sesuai ISO 6508 / ASTM E18. . ASTM E-18; DIN 51917; To the product Kontak. Contact. ZwickRoell. August-Nagel-Straße 11. 89079 Ulm. Tel: +49 (0)7305 10-0. www.zwickroell.com. Perusahaan. Tentang Kami; Lokasi di .Rockwell hardness testing machine by having tighter tolerances on certain parameters. 3.1.7.3 portable Rockwell hardness testing machine—a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-00 ASTM|E0018-00|en-US Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Standard E18 Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic .

Buy ASTM E 18 : 2022 Standard Test Methods for Rockwell Hardness of Metallic Materials from Intertek Inform. Customer Support: +1 416-401-8730. . Portable Rockwell hardness testing machines that cannot meet the direct verification requirements and can only be verified by indirect verification requirements are covered in Test Method E110. The Brinell hardness test identifies the indentation hardness of a desired material. Guidelines for Brinell testing machines and the procedures for performing Brinell hardness tests are standardized through ASTM E10-23: Standard Test Method for Brinell Hardness of Metallic Materials. What Is a Brinell Hardness Test?2.1 ASTM Standards: A 370 Test Methods and Definitions for Mechanical Testing . Last previous edition approved in 2002 as E 18 – 02. 2 In this test method, . hardness test the preliminary test force is 3 kgf (29 N) and total test forces are 15 . Portable Rockwell hardness testing machines that cannot meet the direct verification requirements and can only be verified by indirect verification requirements are covered in Test Method E110. . ASTM E18-18. July 1, 2018 Standard Test Methods for Rockwell Hardness of Metallic Materials 1.1 These test methods cover the determination of the .

test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).

Portable Rockwell hardness testing machines that cannot meet the direct verification requirements and can only be verified by indirect verification requirements are covered in Test Method E110. . ASTM A1038 - Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method. Buy ASTM E 18 : 2022 Standard Test Methods for Rockwell Hardness of Metallic Materials from Intertek Inform. Customer Support: +44 (0)203 327 3140. . Portable Rockwell hardness testing machines that cannot meet the direct verification requirements and can only be verified by indirect verification requirements are covered in Test Method E110.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .1.5 Units— At the time the Rockwell hardness test was developed, the force levels were specified in units of kilograms-force (kgf) and the indenter ball diameters were specified in units of inches (in.). This standard specifies the .

testing is covered by ASTM test method E 18. While all indentation hardness tests generally serve the same purpose, each one has definite advantages that make the test more applicable to certain types of materials and part geometries. Brinell is used primarily on forgings and cast iron. The rebound test is used on large rolls. Vickers Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with . 1 This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation Hardness Testing. Current edition approved Jan .

well hardness test blocks. The standardizing machine differs from a regular Rockwell hardness testing machine by having tighter tolerances on certain parameters. 3.1.7.3 portable Rockwell hardness testing machine—a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and thatQualiRock Digital Rockwell Hardness Tester ensures precise, automatic testing with ASTM E-18 compliance. Ideal for labs and production floors, with 15–30 scales available.

e18 rockwell hardness

astm rockwell hardness testing

ASTM E 18-07 Standard Test Methods for Rockwell Hardness of Metallic Materials is the active and current standard by which Rockwell Hardness Testing is performed, and is also the most frequently used hardness testing method..

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. We routinely get questions about how often hardness testers need to be verified with test blocks by users. ASTM provides guidance in E 18 (Rockwell) and E 92 (Vickers and Knoop), Table A1.1, but the two standards use different terminology and . Guidelines for Determining the Minimum Thickness of a Test Piece Annex A5. Hardness Value Corrections When Testing on Convex Cylindrical Surfaces Annex A6. This standard includes nonmandatory information in the following appendixes that relates to the Rockwell hardness test. List of ASTM Standards Giving Hardness Values Corresponding to .ASTM E18 Full Name. ASTM E18 – Standard Test Methods for Rockwell Hardness of Metallic Materials. Scope. ASTM E18 is a standard test method used to determine the Rockwell hardness of metallic materials. Rockwell hardness is a measure of a material’s resistance to indentation, similar to Brinell hardness.

s22+ drop test

webFernanda Mueller. Blumenau avalia medida polêmica que poderia baixar preço da passagem de ônibus. Pedro Machado. ADIEE Avaí vira contra o Jaraguá e garante o 3º .

hardness tester astm e-18|astm rockwell hardness testing